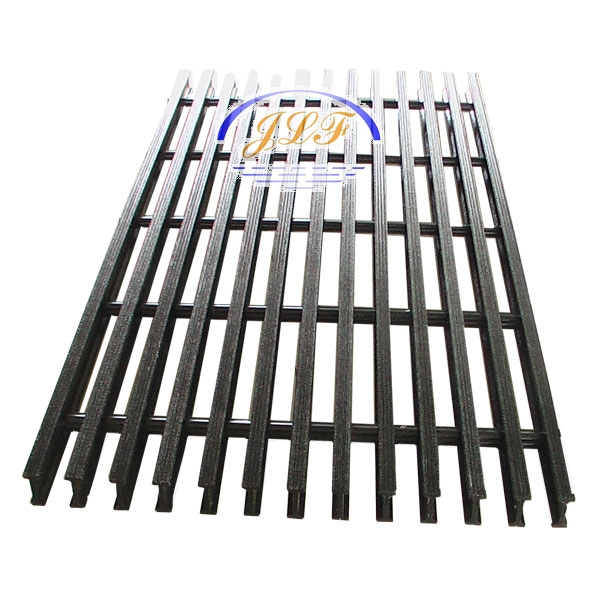

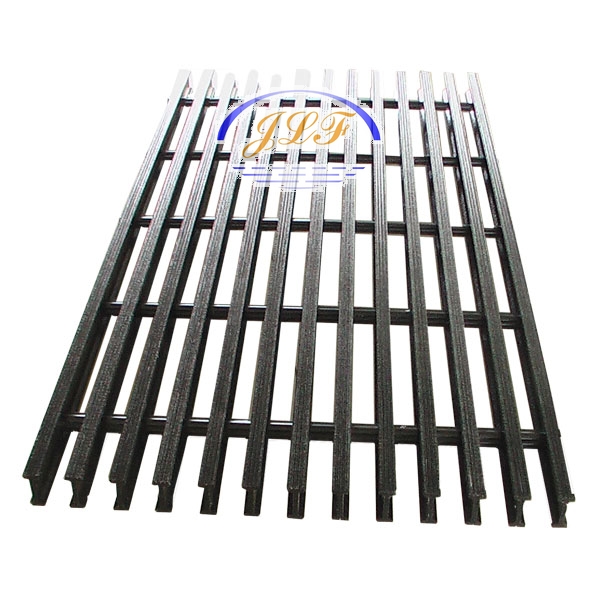

Pultruded Gratings

Craft and raw materials

Constructed from thermosetting resin and fiber reinforcement, the grating is manufactured with the pultrusion process.

The pultrusion fiberglass bar will be of high strength I beam design. All loading members shall be mechanically locked to each other via two spacing bars and central locking rods. Where anti-skid is required, a tough epoxy-quartz coating is applied to the surface of all loading members.

Pultruded FRP fiberglass Gratings Advantages:

The FRP pultrusion grating is designed with a structural integrity commonly associated with steel and aluminum, but without their corrosion problems.

Pultruded fiberglass gratings have the following characteristics:

1. chemical and corrosion resistance

2. high strength to weight ratio

3. light weight and manageable

4. transparent to radio frequencies

5. non-conductive

6. pultruded fiberglass stable

7. non-skid surface

8. cost performance

9. Light Weight

10.UV Resistant

11.Impact Resistant

12. Fire Retardant

13. Safe and Anti-Slip

14.Thermally and Electrically Non-Conductive

15.Maintenance Free

Applications

Jinglue FRP pultrusion grating is an efficient and cost effective solution for all flooring, walkways and decking areas requiring long term performance in aggressive and corrosive environments.

Pultruded gratings are extensively applied in the fields of chemical industry, power, electroplating, boats and water treatment as the platform, ladder steps, gutter cover, bridge corridor and waste water trays.

Specifications & load capacity

When customer design and decide the size and type of the loading members, the gratings panel sizes, you can refer our tablet of Specifications & load capacity .